Home, Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index

A head gasket failure is always bad news. A blown head gasket means the gasket may be leaking coolant into the crankcase (which can ruin the bearings), or that the gasket is leaking compression (which causes misfire and a loss of power and fuel economy). If the head gasket is leaking coolant, your engine won't run long because it will quickly overheat. If it is leaking compression, you can keep driving but you'll notice a significant loss of power.

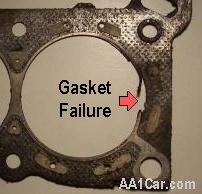

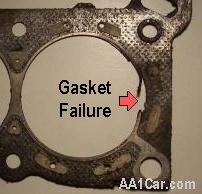

Any number of things might have caused the head gasket to fail. One of the most common causes is engine overheating. If the engine overheats for any reason and gets really, really hot, thermal expansion between the cylinder head and block can literally crush the head gasket armor around one or more cylinders (usually the center cylinders because heat concentrates here more than any other place in the engine). Once the armor has been crushed, it loses its seal and starts to leak compression and/or coolant. The gasket quickly erodes and the condition gets worse and worse until it can't be ignored any longer.

If overheating was the cause of the head gasket failure, it's important to figure out why the engine overheated so it doesn't happen again. If the water pump, radiator, hoses or engine is leaking coolant, the leaks have to be found and fixed. If the engine got too hot because the cooling fan wasn't working or the radiator was clogged, these problems need to be diagnosed and repaired. Otherwise, the head gasket may fail again if the engine is running hot.

Sometimes a head gasket fails because the OEM head gasket is a crappy gasket. That's a nice way of saying the engineer who designed the gasket failed to make it robust enough to withstand the rigors of everyday driving, especially as the engine accumulates a lot of miles. Or, the materials that were used in the OEM gasket turned out to be not the best choice for your engine.

Years ago, Ford had a major problem with premature head gasket failures in 1995 Windstar minivans with the 3.8L engine because the OEM gasket just didn't stand up very well. The same thing happened to many early General Motors 2.4L Quad Four engines, and many first generation Dodge Neon 2.0L engines. In many of these engines, the OEM head gasket started to leak after 50,000 to 60,000 miles. These problems are history now, but similar situations may crop up at any time.

Most last model engines now use Multi-Layer Steel (MLS) head gaskets because they are much stronger and more durable than nonastestos or graphite cylinder head gaskets. Aftermarket MLS head gaskets are now available for many "problem" engines that are known to eat head gaskets, including the early Neon 2.0L engines and Toyota 3.4L engines.

Some engines are also hard on head gaskets because they develop hot spots in the cylinder head between the center cylinders. These include older Honda Civic 1.3 and 1.5L engines. Most of the aftermarket replacement gaskets for these applications include a special reinforcement between the center cylinders to resist thermal crush so the gasket won't fail.

On Mitsubishi 3.0L V6 and Toyota 3.0L engines, the armor around the combustion chambers on the OEM gasket often cracks as a result of thermal motion between the cylinder head and block. Many aftermarket replacement gaskets for these engines have a non-stick coating that provies some "give" so the gasket doesn't self-destruct as the engine heats up and cools down over and over again.

Head gaskets can also fail if an engine has a preignition or detonation problem. Over time, it will increase the stress on the head gasket and cause it to fail. Preignition means a hot spot inside the combustion chamber is causing the fuel to ignite before the spark plug fires. This can be very damaging to the pistons. Preignition can occur when the engine is running too hot because of a cooling problem.

Detonation may occur if spark timing is over-advanced or the fuel mixture is too lean, or the EGR system is not working, or there is too much compression and/or not enough octane in the fuel. Detonation causes spark knock, which makes a pinging or rattling noise when the engine is lugging or accelerating under load. In many cases, the cause is a build-up of carbon deposits inside the combustion chamber and on the tops of the pistons fro short trip stop-and-go city driving. You need to get the car out on the road and blow the carbon out.

If a head gasket on a recently installed or rebuilt engine fails, chances are the problem was "installer error". That's a nice way of saying the guy who assembled your engine screwed-up. Maybe he didn't tighten down the head bolts in the proper sequence or to the specified torque. Maybe the torque wrench he used was inaccurate, or he didn't follow the proper tightening procedure. Maybe the bolt threads were dirty, or the bolts were damaged or stretched. Or maybe the surface of the cylinder head or engine block were not clean, smooth or flat. Any of these things can cause a poor seal and result in a premature head gasket failure.

For bimetal engines with composition gaskets, the recommended surface finish is typically 20 to 50 microinches RA . This compares to 60 to 120 RA for cast-iron engines with the same type of gaskets. If the engine uses an MLS head gasket, the recommended surface finish may be 20 RA or less.

Flatness is critical, too. On most pushrod engines with cast iron heads, there should be no more than 0.003 in. (0.076 mm) out-of-flat lengthwise in V6 heads, 0.004 in. (0.102 mm) in four-cylinder or V8 heads, and 0.006 in. (0.152 mm) in straight six-cylinder heads. If the engine has aluminum heads, there should be no more than 0.002 in. (0.05 mm) out-of-flat in any direction.

If you are replacing a head gasket yourself, make sure the surface of the engine block and cylinder head are clean, smooth and flat. Follow the gasket supplier's installation instructions. DO NOT use sealer on a soft faced or coated head gasket, or an MLS head gasket. Sealer is generally only required on some one-piece steel uncoated head gaskets.

Look up the cylinder head bolt torque specifications for your engine, and tighten the bolts in the specified sequence to the specified torque using a torque wrench. The head bolts must be tightened accurately to properly load and seal the head gasket. If this is not done, the head gasket may leak causing a repeat head gasket failure.

More Engine Repair Articles:

More Engine Repair Articles: Click Here to See More Carley Automotive Technical Articles

Click Here to See More Carley Automotive Technical Articles